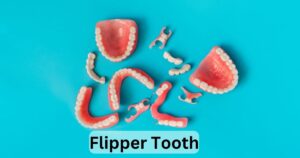

Dentures, essential prosthetics used to restore oral function and aesthetics, consist of a composite of materials carefully selected for their functionality and durability. Primarily crafted from acrylic resin, these dental appliances mimic the appearance and function of natural teeth and gums.

In partial dentures, metal frameworks provide added support and stability, while flexible materials offer comfort and adaptability. Some dentures incorporate porcelain or ceramic components for their lifelike aesthetics and durability. Recent advancements also introduce nylon-based materials, enhancing flexibility and fit.

The selection of denture materials depends on factors like oral health, comfort requirements, and budget considerations. Understanding the composition of dentures illuminates the intricacies behind their construction, highlighting the importance of material choice in ensuring optimal functionality, comfort, and natural aesthetics for individuals seeking dental restoration.

Acrylic Resin: Primary Material in Dentures

Sure, let’s break down the information into 100-word sections for each point.

Properties of Acrylic Resin

Acrylic resin, chiefly polymethyl methacrylate (PMMA), possesses properties ideal for dentures. Its aesthetics allow color matching to natural teeth and gums, ensuring a realistic appearance. Durability is a hallmark, resisting wear and retaining shape. Its lightweight nature ensures comfort for wearers, while its malleability allows easy adjustments to fit.

Aesthetics: Acrylic resin can be color-matched to resemble natural teeth and gums, providing a lifelike appearance.

Durability: It withstands regular wear and tear, maintaining its shape and structure for an extended period.

Lightweight: Dentures made from acrylic resin are relatively lightweight, ensuring comfort for wearers.

Ease of Adjustment: Dentists can easily modify and adjust the fit and appearance of acrylic dentures.

Fabrication Process:

The process begins with precise impressions of the oral cavity, creating models. Acrylic resin, in a dough-like form, is shaped over these models to craft the denture base and teeth. After curing, meticulous trimming and polishing ensure proper fit and aesthetics.

Impression Taking: Dentists take precise impressions of the patient’s oral structures.

Model Creation: These impressions are used to create precise models of the mouth.

Acrylic Molding: The acrylic resin is molded onto the models to form the denture base and teeth.

Finishing: After curing, the dentures undergo final trimming and polishing to ensure proper fit and aesthetics.

Advantages:

Affordability is a standout advantage of acrylic resin dentures, offering cost-effective solutions. Their repairability allows easy modifications and fixes by adding more acrylic.

Affordability: Acrylic resin dentures are relatively cost-effective compared to other materials.

Repairability: They are easily repaired or modified by adding more acrylic.

Considerations:

While prone to potential staining over time, acrylic resin may not boast the same longevity as some alternative materials, occasionally necessitating replacement after several years of use.

Staining: Acrylic resin may be prone to staining over time.

Strength: It may not be as durable as some other materials, potentially requiring replacement after several years of use.

Acrylic resin-based dentures continue to be a popular choice due to their affordability, adaptability, and satisfactory aesthetic results, making them a reliable option for dental restoration.

Flexible Denture Materials

Flexible denture materials represent a contemporary advancement in dental prosthetics, offering distinct advantages over traditional rigid options.

Crafted from thermoplastic materials like nylon or polyester, these dentures boast an elastic quality, bending under pressure without breaking. This elasticity ensures a comfortable fit by conforming to the mouth’s contours, reducing sore spots often associated with rigid dentures. Their lightweight design contributes to increased wearer comfort.

Fabricated through injection molding, these materials allow for customized dentures tailored to an individual’s oral anatomy. The gum-like translucency of flexible materials provides a more natural appearance, blending seamlessly with the gums and enhancing aesthetics.

While flexible dentures offer enhanced comfort and a more natural appearance, they may entail higher costs due to specialized materials and manufacturing processes. Additionally, while durable, repairing these dentures may require specialized expertise in addressing common denture problems.

Porcelain or Ceramic Elements

Porcelain or ceramic elements are pivotal components integrated into dentures, primarily designed to emulate the natural appearance of teeth and enhance aesthetics. Renowned for their striking resemblance to natural teeth, these materials offer a realistic look in terms of color, translucency, and texture. Crafted meticulously by skilled technicians, porcelain or ceramic teeth are individually tailored to match the shape, size, and shade of existing natural teeth, ensuring a seamless and lifelike smile.

Beyond their aesthetic appeal, porcelain or ceramic elements exhibit exceptional durability and resilience. Resistant to wear and staining due to their non-porous nature, these materials maintain their color and appearance over time, contributing to prolonged aesthetics.

The fabrication process involves intricate craftsmanship to create each artificial tooth, followed by careful integration into the denture base. While these elements offer outstanding aesthetics and durability, their rigidity compared to natural teeth may exert additional stress on the denture base.

However, their lifelike appearance and durability often come at a higher cost compared to alternative denture materials. Despite this consideration, the unparalleled natural look and lasting aesthetics make porcelain or ceramic elements a preferred choice for individuals seeking highly realistic and long-lasting dentures, accentuating smiles with lifelike charm and endurance.

Nylon-Based Denture Material

Nylon-based denture materials mark a significant advancement in dental prosthetics, offering a blend of comfort and resilience unparalleled in traditional options. Crafted from a thermoplastic nylon resin, these dentures showcase remarkable flexibility, bending under pressure without succumbing to breakage. This pliability ensures a comfortable fit, reducing the occurrence of sore spots common with rigid dentures.

The fabrication process involves specialized injection molding techniques, allowing the nylon material to be precisely shaped into the denture, customized to fit the individual’s unique oral anatomy. This customization contributes to increased wearer comfort and functionality.

These denture materials excel in comfort and durability, adapting seamlessly to the mouth’s contours while maintaining robustness and lasting functionality. Despite potential higher costs due to specialized materials and manufacturing, nylon-based dentures stand as a commendable choice for individuals prioritizing comfort and long-term resilience in their dental solutions.

Comparing Materials for Denture Construction

Denture construction utilizes various materials, each offering distinct advantages and considerations. Acrylic resin, the most common, is prized for its affordability and ease of adjustment, yet it might stain over time and lack the durability of other materials. Metal frameworks, primarily cobalt-chromium alloy, provide exceptional strength and stability but might be visible and costlier.

Flexible denture materials like nylon offer heightened comfort and adaptability, yet repairs may require specialized expertise. Porcelain or ceramic elements replicate natural teeth remarkably but come at a higher cost and with increased rigidity. Each material presents a unique blend of properties—be it durability, aesthetics, comfort, or cost. Acrylic resin stands as a versatile, cost-effective option, while metal frameworks provide stability.

Flexible materials prioritize comfort, and porcelain/ceramic elements offer lifelike aesthetics. The choice often depends on individual needs, considering factors like budget, comfort, aesthetics, and longevity when selecting the most suitable material for denture construction.

Benefits and Challenges of Different Denture Materials

Certainly! Here’s a chart outlining the benefits and challenges of different denture materials:

| Denture Materials | Benefits | Challenges |

| Acrylic Resin | – Affordability<br>- Ease of Adjustment | – Prone to Staining<br>- Lesser Durability |

| Metal Frameworks | – Exceptional Strength<br>- Stability | – Visibility<br>- Higher Cost |

| Flexible Materials | – Increased Comfort<br>- Adaptability | – Repair Complexity<br>- Potential Costliness |

| Porcelain/Ceramic Elements | – Lifelike Aesthetics<br>- Durability | – Increased Rigidity<br>- Higher Cost |

This chart provides an overview of the advantages and challenges associated with different denture materials, aiding in comparing their distinct properties and considerations for individuals seeking dental prosthetic solutions.

Innovative Advances in Denture Material Technology

Innovative advances in denture material technology continuously revolutionize dental prosthetics, introducing cutting-edge materials and techniques to enhance comfort, aesthetics, and functionality.

Precision Customization

Precision customization in denture technology leverages advanced techniques like 3D printing, enabling tailored solutions for individual oral anatomy. Through detailed digital scans, this innovative approach ensures dentures are meticulously crafted to fit the unique contours of a patient’s mouth.

The process allows for exacting adjustments, resulting in dentures that offer superior comfort and functionality. Precision customization not only enhances the fit and feel of dentures but also streamlines the manufacturing process, offering quicker production and personalized solutions that align with the specific needs of each patient.

Rapid Prototyping

:Rapid prototyping, a pivotal aspect of modern denture manufacturing, utilizes advanced technology to swiftly create prototypes and finalized dentures. This process involves computer-aided design (CAD) and 3D printing, enabling quick and precise production based on digital scans of patients’ oral structures.

Rapid prototyping expedites the denture creation timeline, allowing for rapid adjustments and iterations. This technology streamlines the manufacturing process, providing dentists and patients with faster turnaround times for custom-fit dentures, enhancing the overall patient experience and facilitating more efficient dental care.

Bioactive Materials

Bioactive materials used in dentures promote tissue growth and integration within the oral environment. These innovative materials encourage better interaction with oral tissues, potentially enhancing denture longevity and improving overall oral health by supporting a more natural integration with the mouth’s anatomy.

Tissue Integration

Tissue integration in denture technology refers to the seamless bonding between the denture and oral tissues. Advanced materials encourage better tissue growth and adherence, promoting a more natural integration with the mouth’s environment. This integration aids in improving stability and comfort while wearing dentures.

Enhanced tissue integration reduces movement or discomfort often associated with ill-fitting prosthetics, fostering a more secure and comfortable fit for wearers. It ensures a harmonious connection between the denture and oral tissues, optimizing functionality and contributing to overall oral health.

Enhanced Durability

Enhanced durability in denture materials signifies superior resistance to wear, breakage, and degradation over time. These advanced materials, often incorporating innovative compositions or technologies, offer prolonged longevity compared to traditional options.

By withstanding daily wear and tear, they maintain their structural integrity, reducing the need for frequent replacements or repairs. Enhanced durability not only ensures a longer lifespan for dentures but also promotes sustained functionality, providing wearers with reliable and long-lasting dental prosthetics that withstand the rigors of everyday use.

Nanotechnology:

- Enhanced Strength: Nanomaterials provide stronger and lighter dentures with improved mechanical properties.

- Stain Resistance: Nanoparticles offer enhanced resistance to stains and wear, maintaining aesthetics over time.

Smart Materials:

- Self-Adaptability: Smart materials respond to environmental changes, adapting to temperature or moisture for increased comfort.

- Antibacterial Properties: Some materials possess inherent antibacterial properties, promoting oral health.

Innovations in denture materials aim to address longstanding challenges, offering patients improved comfort, durability, and oral health while pushing the boundaries of traditional dental prosthetics.

Factors Influencing Denture Material Selection

The selection of denture materials is a multifaceted decision influenced by diverse factors that collectively shape the most suitable choice for an individual’s oral restoration. Oral health considerations stand paramount, addressing gum sensitivity and bone structure to ensure optimal comfort and support. Aesthetics and comfort play pivotal roles, with preferences leaning towards materials offering a natural appearance and a comfortable fit that minimizes irritation.

Functional aspects such as chewing ability and speech enhancement guide material selection, necessitating stability and strength for efficient chewing while aiding in clearer speech. Cost-effectiveness and longevity weigh significantly, influencing choices based on budget considerations and the desire for durable materials that resist wear or breakage over time.

The guidance and recommendation of dental professionals hold immense importance, integrating professional advice with personal preferences and oral health requirements. This holistic approach ensures the material chosen aligns with individual needs, optimizing comfort, functionality, aesthetics, and longevity for a satisfying denture experience. Ultimately, the amalgamation of these factors orchestrates a comprehensive and tailored selection process, culminating in the optimal denture material choice for each unique individual.

FAQ’s

What is the best material to use for dentures?

Porcelain: They are the most natural-looking dentures. They are durable, resilient, and very long-lasting. A lot of people nowadays prefer porcelain dentures because of their immaculate aesthetic appeal. Porcelain dentures are also waterproof and support organic jaw movements.

What is the pink part of a denture made of?

The pink bases are usually made of hard based acrylic/polymer which is molded around and chemically joined to the teeth.

Which denture teeth is best?

If you have a couple of missing teeth, partial dentures are a good option. If you have all of your teeth missing, complete dentures may be necessary. If you are looking for a more stable and secure option, implant-supported dentures or overdentures may be the right choice.

What are real dentures made of?

Dentures are removable false teeth made of acrylic (plastic), nylon or metal. They fit snugly over the gums to replace missing teeth and eliminate potential problems caused by gaps.

Can you sleep with dentures in?

How Long Should You Wear Dentures? You may need to wear your dentures most of the time for the first few days, including during sleep. Once your mouth adjusts to your dentures, you should avoid wearing them overnight.

Conclusion

Dentures, crafted from a variety of materials like acrylic resin, metal frameworks, flexible compounds, and porcelain or ceramic elements, embody a convergence of innovation and functionality in dental prosthetics. Each material offers distinct advantages, from affordability to enhanced aesthetics or durability.

The selection process involves a careful balance between individual needs, oral health considerations, comfort preferences, and budget constraints. Innovative advancements continually shape the landscape of denture materials, aiming to improve comfort, longevity, and natural appearance.

The diversity in materials ensures that patients can find personalized solutions, underscoring the importance of choosing the most suitable material to restore smiles and oral functionality for an improved quality of life.